Sharpening with Diamond Grinding Wheels

- on the Tormek water-cooled sharpening system

Professional sharpening of all edge tools

At Tormek, we have been dedicated to developing the best sharpening solutions for different types of edge tools since 1973. To offer innovative and user-friendly products of the highest quality is and remains essential to us. We currently have four models of our water-cooled sharpening system for most edge tools out there, and two different knife sharpeners – one for commercial kitchens and one for the home chef. Whether you are a professional woodworker, a DIY enthusiast or a cook, Tormek helps you maintain the sharpness of your tools, which in turn raises the quality of your work. Because sharpening, that's our thing.

Our sharpening machines all have different applications. Whatever you need to sharpen, to maximum sharpness at maximum precision, there is a Tormek machine to meet your needs. If you have a lot of different tools to sharpen, and perhaps use them professionally, there is the powerful Tormek T-8 model for water-cooled sharpening of all your edge tools. For the DIY enthusiast or woodworker with limited space, there is the compact Tormek T-4 Original model, which also comes equipped for hunting and outdoor as the Tormek T-4 Bushcraft. All of the water-cooled sharpening machines are compatible with Tormek's wide-ranging jig system and accessories.

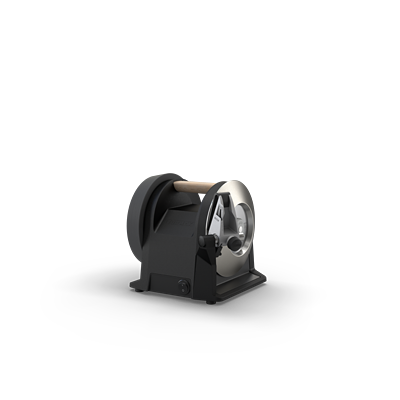

For the professional chef who works in a restaurant or with other food preparation, we offer the professional knife sharpener Tormek T-2 Pro Kitchen Knife Sharpener. We have also developed the first real knife sharpener for the dedicated home chef – the Tormek T-1 Kitchen Knife Sharpener. Both of these machines come with a fine-grained diamond grinding wheel and have a patented guide for quick and easy setting of the sharpening angle for most types of kitchen knives.

Using the Tormek method, you can be sure that you grind away the smallest possible amount of steel every time you sharpen, giving your tools a longer service life. You have the possibility to exactly repeat the existing angle, along the entire bevel of the tool, and the grinding wheel rotates at a low rpm. Everything in order to minimize the amount of steel you grind away. In addition, you avoid overheating so that the steel never loses its tempering. In our water-cooled sharpening system, the water acts as a coolant, while also washing the steel particles from the sharpening down into the water trough.

Our knife sharpeners for kitchen knives are used without water and instead use a magnet to collect the steel particles. In addition, they are equipped with fine-grained diamond grinding wheels, which also rotate at a low rpm. This means that the sharpening will be easy on you as well as your knife.

In order to achieve maximum sharpness, it is important that you finish the sharpening by honing and polishing your tool on the honing wheel. As we say so often, this is where the magic happens. It is when you hone the tool that you remove the burr that appears during sharpening and get a razor-sharp edge that lasts for a long time. Remember to always hone your tool with the honing wheel rotating away from the edge of your tool (edge trailing), and to devote some extra time and love to it. To make the sharpness last even longer, you can also hone your tools between sharpenings for maintenance purposes, until the next time it is due to be thoroughly sharpened.

Tormek's jigs for the water-cooled sharpening system and the patented guide in our knife sharpeners provide you with full control and repeatability when sharpening. By coloring the bevel with a marker, you can quickly and easily find and repeat the existing angle. If you want to give your tool a new bevel angle, you can instead use the WM-200 AngleMaster for your water-cooled sharpening machine, or easily set the desired angle in the patented guide on your knife sharpener in order to obtain a new precise angle. Then you can repeat your new angle using the marker method the next time you sharpen the tool.

A wide range of unique and patented jigs and accessories is available for Tormek's water-cooled sharpening system to allow you to sharpen almost any type of edge tool. Chisels, scissors, drill bits and so much more, everything will be at its sharpest on a Tormek.

A cook wants to have sharp kitchen knives á la minute. That's why Tormek's knife sharpeners for kitchen knives have been developed in order to quickly, easily and cleanly sharpen the vast majority of knives you can find in a kitchen.

Celebrating 50 Years of Sharpness

Powerful and versatile water-cooled sharpening system

Create your own water-cooled sharpening system

Compact water-cooled sharpening system for all edge tools

Sharpen your axes and knives for hunting and outdoor activities

Professional knife sharpening in no time

The first real knife sharpener for the home chef

FULL CONTROL OF YOUR SHARPENING

For precise, controlled and repeatable sharpening

Find the right grinding jig

Subscribe to our newsletter and be among the first to find out about our latest product developments. After subscribing through this registration form you will get the chance to download the HB-10 Tormek Handbook as a PDF-document in available languages.

Don't worry if you're already registered to our newsletter – it will not matter. The email address you share with us will only be used to send you the newsletter. Read our Privacy Policy Opens in new window. for more information.

Opens in new window. for more information.